Hybrid Making Lab

The Hybrid Making Lab serves as a college-wide resource, providing both students and faculty with access to fabrication equipment and a production space within a multidisciplinary setting. Open to all Westphal students and faculty, the lab is open to host individual classes and various college-wide workshops throughout the academic year, promoting interdisciplinary design, research, and teaching.

Featuring a range of micro and small-scale tools tailored for model making and small-scale prototyping, the Hybrid Making Lab boasts three Universal Laser Cutters, CNC routers, and a variety of 3D printers.

The Hybrid Lab has regular weekly hours during the school year. During the fall, winter, and spring term the Lab is open every day, while during the summer term the hours may differ. The Lab is general closed for the holidays and term breaks. Hours are posted outside of the Hybrid Making Lab.

To utilize the Hybrid Making Lab, all students are required to attend an orientation session, covering the fundamental use of lab tools and the laser cutter.

Laser Cutting Guidelines at the Hybrid Making Lab

For laser cutting guidelines, cutting file guidelines, and laser cutter materials, please refer to the provided PDF documents:

General Laser Cutting Guidelines [PDF]

Cutting File Guidelines [PDF]

Laser Cutter Materials [PDF]

3D Printing

The Hybrid Making Lab offers exclusive access to two types of 3D printers for Westphal students, faculty, and staff. Individuals must be affiliated with Westphal College to use the 3D printers in the lab. Before visiting the Hybrid Lab during its operating hours, review the following instructions:

File Requirements

All printers accept OBJ or STL files.

Ensure that your files are volumetric and "watertight."

The printers will not process single surfaces or lines/curves, as including such elements may result in rejection or failure of the print.

Printer details

Both printer types support surface details, with a general recommendation that file elements be no smaller than 1/8" thick.

Thinner surfaces and members may print well but are prone to breakage during the cleaning process.

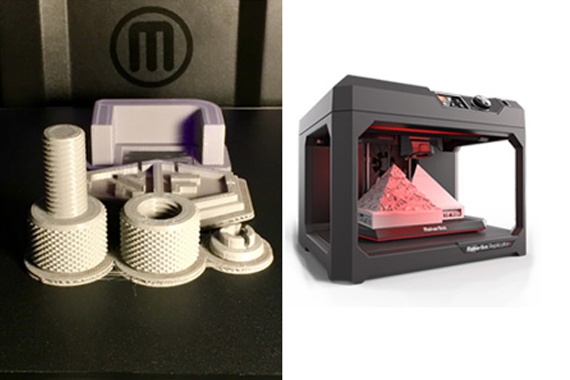

MakerBot Replicator

Most readily available and inexpensive printer.

Prints white PLA plastic with a required raft and supports.

Optimal print area: 6"x6"x6" (xyz).

Print cost: $0.06 per gram.

Common issue: Peeling up and warping of prints with large surface areas.

Fuse 1

Ideal for movable parts, multiple prints, and larger finished prints.

Prints with black/dark grey nylon powder.

No need for supports but requires extraction from powder and thorough scrubbing before finishing.

Optimal print area: 6"x6"x10" (xyz).

Print cost: $0.20 per milliliter.

Common issue: Fine grainy texture due to the use of nylon powder.